Plastic waste: How a solution became a problem, and how to fix it

The world’s plastic crisis has recently yielded new developments in engineering, political action, and consumer awareness. Last year, European Parliament voted to ban single-use plastic products by 2021, and China abrogated as the world’s de facto repository for discarded plastics. It is clear that plastic consumption habits are unsustainable, and tackling the issue requires an increasingly multidisciplinary approach. The concern for the future of our planet is mutual, affecting both the grocery shopper and the biochemist developing a novel formula for the packaging of those groceries.

To solve a problem, we need to understand it, which in this case means studying the plastic waste stream. Essentially, we need to determine what is plastic, and how it eventually becomes waste.

Defining plastic: it’s simple and it’s complicated

At one time the word plastic simply meant “pliable and easily shaped.” It is easy to get lost in the taxonomy of plastics from conventional to bio-based, non-recyclable to biodegradable. As modern synthetic plastics were invented about a hundred years ago, so-called “life cycle thinking” was not imperative. The focus was on the convenient qualities of this revolutionary invention.

It was not until recently that plastics became nested under a category of materials called polymers. The definition encompasses what are called conventional plastics and bio-based plastics. Conventional plastics such as polyethylene (PE) and polypropylene (PP) are made from petroleum. In other words, they are fossil-based and made from non-renewable resources. Bio-based plastics are made from renewable biomass sources.

And this is where the plot thickens: a product made from potato starch can be classified as plastic. This is because raw-materials essentially have nothing to do with what is categorized as plastic. Plastics are a wide range of polymers constructed from long repeating chains of building blocks that can be moulded into shape. Both your skin collagens and products made from petroleum consist of polymer chains that meet this criteria and hence, can be called plastics.

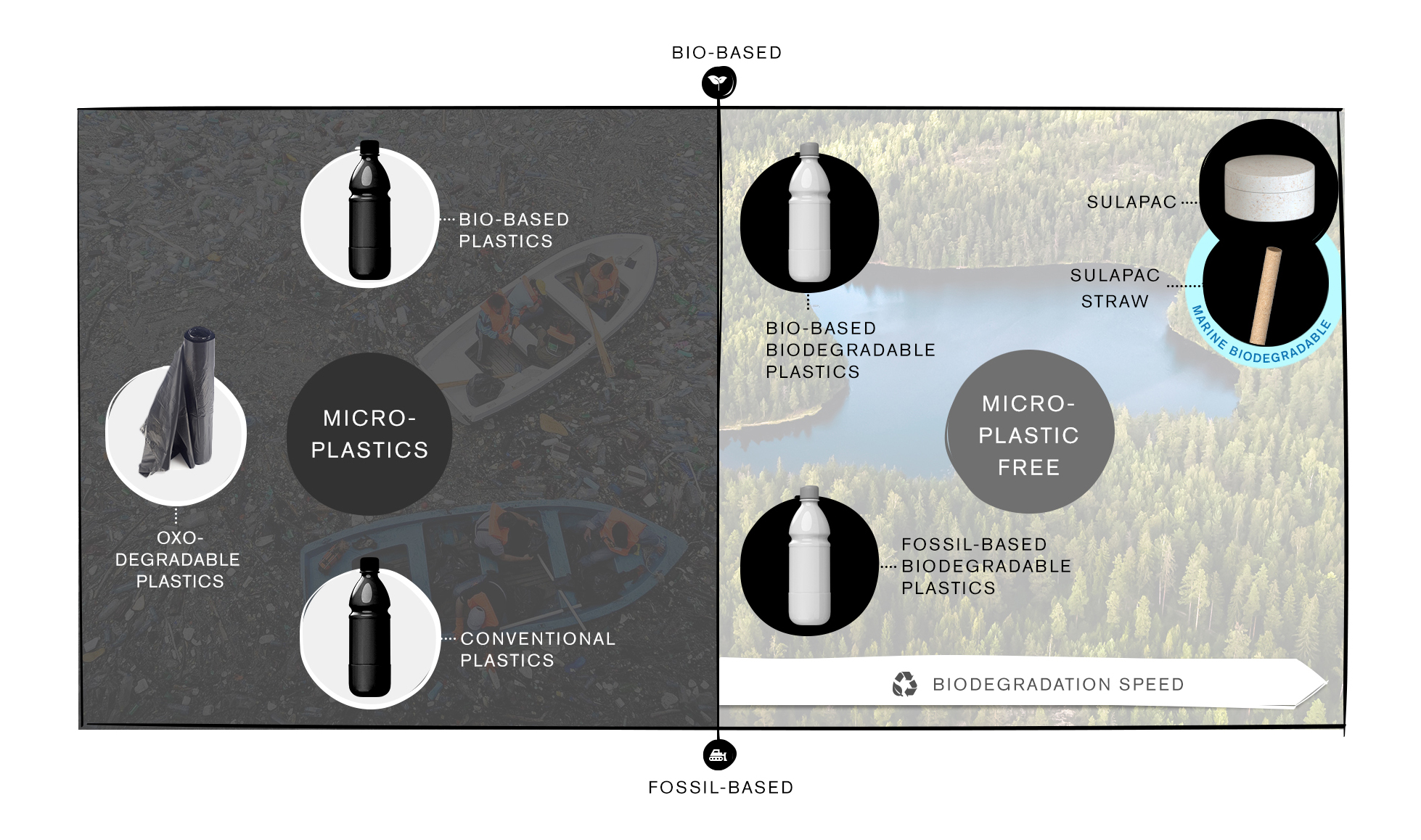

And it gets even more complex. You might think that those bio-based plastics, such as ones made from sugarcane, are automatically environmentally friendly. This is not always the case. Whether plastic is bio-based or fossil-based, their polymer structure may be exactly the same, and both types can release microplastics.

The confusion between degradable and biodegradable

The process of microplastic release essentially distinguishes whether plastics are just degradable or truly biodegradable. An example of a common confusion in this area is the several reported cases of greenwashing, with oxo-degradable plastics having misleadingly been labeled as biodegradable. Due to specific additives in their formula, these plastics disintegrate into microplastics faster than conventional plastics do. In other words, such plastics degrade at an accelerated pace, but do not biodegrade.

When plastics are truly biodegradable, they eventually decompose into water, carbon dioxide and biomass. However, in order for many biodegradable plastics to get through this process, material needs to be very thin and a specific environment such as an industrial compost is necessary. And even when these conditions are met, biodegradation speed tends to be very slow. An example of such category is polylactic acid (PLA). Many products made from PLA look exactly like conventional plastics but cannot be mechanically recycled with conventional plastics. Since PLA biodegrades too slowly in nature, the products made from PLA do not qualify as marine or fresh water biodegradable.

Plastics are traditionally categorized according to their raw material source and biodegradability. Further, we suggest that materials should be divided into microplastic releasing and microplastic-free categories.

Improving recyclability of materials

In theory, the life cycle of plastic products has lengthened through the establishment of mechanical plastic recycling infrastructure. Sadly, this process has its limitations. Even though plastic can be mechanically recycled many times, most plastic waste remains unused. According to National Geographic, only nine percent of the plastic produced globally is recycled. For one, this means that we need to become better at recycling and come up with improved practices for sorting waste. But as we are still far from reaching even satisfactory rates of recycling, we need to address the issue of a massive quantity of plastics ending up in our natural environment.

According to Ellen McArthur Foundation, if nothing changes there will be more plastic waste than fish in the ocean by 2050. Since plastic is being littered, we need to reduce the consumption of plastics but also, develop bio-based, marine and fresh water biodegrading materials. New alternatives are needed especially to single-use plastic products, which often end up accidentally in natural environment. Most importantly, the most crucial measure in tackling the plastic waste issue is building more efficient recycling infrastructure for all types of materials.

While 100% recycling rate of materials should be the ultimate goal, the materials produced should also be safe and toxic-free for our ecosystem. Biodegradable plastics hold high value to the society through their ability to provide opportunities to return carbon to soil as compost and to create new raw materials. The best way to recycle biodegradable materials is through organic recycling, other say, industrial composting and anaerobic digestion. Unfortunately these processes are not efficiently in use in all European countries. Therefore, production of clean energy via incineration is currently a good alternative. There is also a growing interest towards chemical recycling, synthetic gasification and home composting methods.

Navigating the plastic waste issue, it is clear that the very definition of plastic has become ambiguous. Confusion around plastics has led to the misleading use of terms “bio” and “green” in association with materials. To clarify the definitions and help consumers make truly sustainable choices, materials should be divided into microplastic releasing and microplastic-free materials. Microplastic releasing materials cannot be digested by naturally-occurring microorganisms, and therefore, remain in the nature for hundreds of years. Microplastic-free materials can be digested by naturally occurring micro-organisms, and eventually biodegrade to CO2, H2O and biomass, if they accidently end up in the natural environment.

Developing new alternatives to plastic

Our mission at Sulapac is to save the world from plastic waste. Sulapac’s contribution to the fight against the plastic waste crisis is the development of recyclable and microplastic-free alternatives to plastic, made from safe, renewable and sustainably sourced raw materials.

While we are on a mission of providing truly sustainable alternatives for conventional materials, we know that a plastic-waste free world can only be achieved through everyone’s participation. What can you do to drive this change?

Dr. Suvi Haimi

CEO, Co-founder

PhD in Medical Biomaterials

Sulapac is a fully biodegradable and microplastic-free material made of sustainably sourced raw materials that plastic manufacturers can use with their existing machinery. Sulapac products are designed for brands that want to eliminate plastic waste and demonstrate a genuine commitment to sustainability using premium ecological material. The company was founded in 2016 by Suvi Haimi and Laura Tirkkonen-Rajasalo and is based in Helsinki, Finland.