Towards the plastic waste-free future

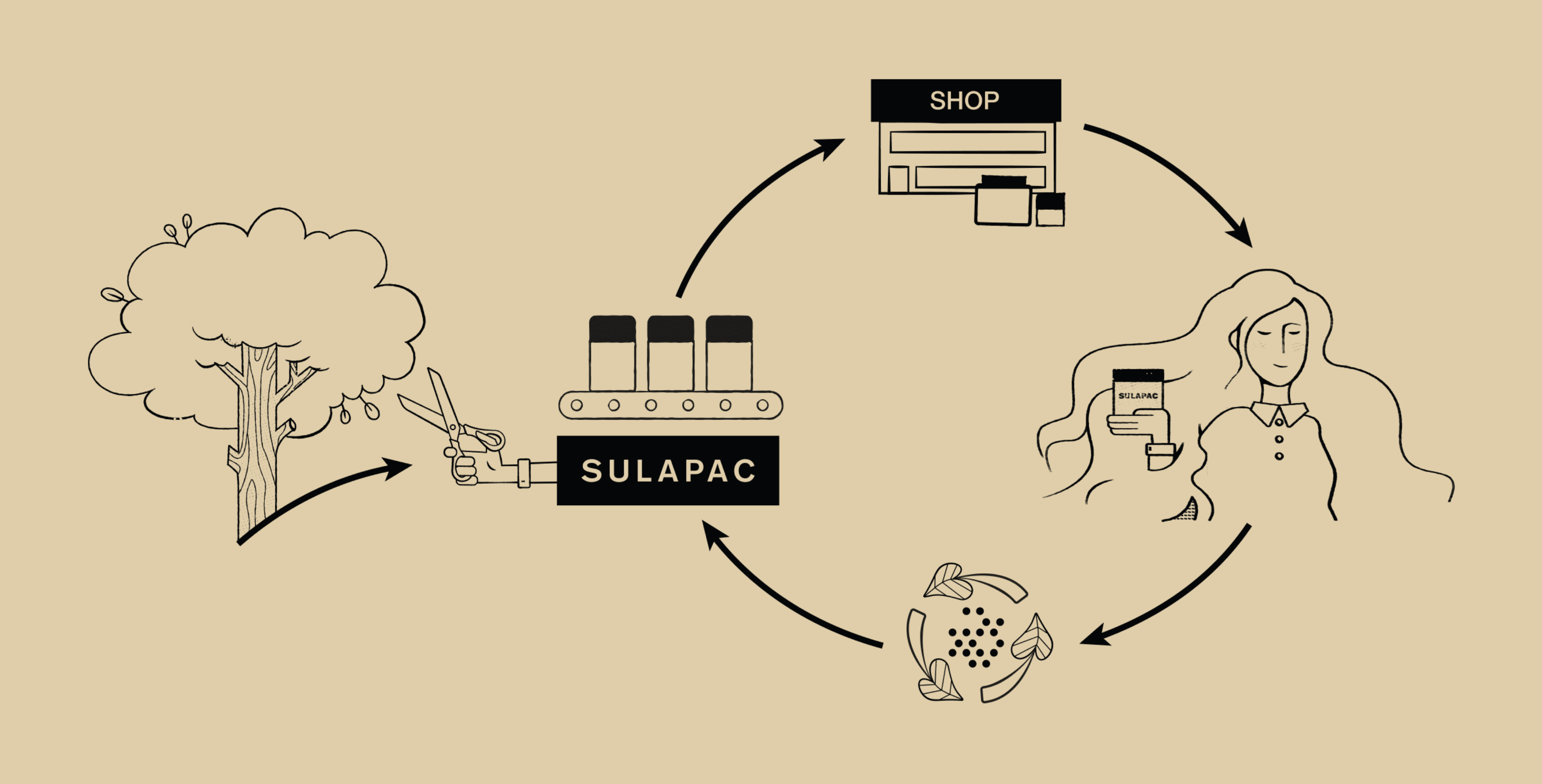

All Sulapac materials have been designed to be recycled via industrial composting, but unfortunately the recycling infrastructure and legislation around it varies between countries. The collection, processing and regulatory framework are currently in the development phase. However, we can’t just wait and see what happens. We have to act now. Our mindset, since the beginning, has been to solve problems. We can’t wait. We have to act now. Thus, we are developing a take back system. This is our pilot together with Vida, Karhumuovi and Ruohonjuuri.

‘Vida Kuulas’ packaging is made of bio-based Sulapac material. The empty jars will be returned to Ruohonjuuri that then delivers them to Karhumuovi. There, the recycled r-Sulapac material is used for ‘Naturn Riite’ urns. No permanent microplastics will be released during or after this cycle.

“We’ve come a long way replacing conventional plastics, but our ambition is to have impact at large. It requires more collaboration – and continuous improvement of our products and processes. Our new ‘Take Back Sulapac’ program is the next phase towards the plastic waste-free future and minimized environmental footprint”, says Dr. Suvi Haimi, CEO and Co-founder of Sulapac.

Accelerating circular economy together

The take back pilot is a joint effort with four dedicated forerunners. In the end of 2020 a new supplement product line, Vida Kuulas, was launched in collaboration with Sulapac. They were keen to take part of the take back premiere together with the ecological retailer Ruohonjuuri.* Karhumuovi was a natural fit for the end-of-life development of the take back pilot with their beautiful and environmentally friendly pet urn, Naturn Riite.

*The shops include Kamppi, Iso Omena, Redi, Ainoa, Oulu, Tampere, Turku in Finland. The pilot takes place 8.6.-30.11.2021.

Later this year, after we have gathered learnings from our pilot, the ‘Take Back Sulapac’ program will expand to other markets.

Take it back, make an impact.

This is the carbon impact

Replacing newly made virgin material with the recycled r-Sulapac saves resources and reduces greenhouse gas emissions. We call this carbon impact.

* Screening level carbon footprint calculation by an independent consultant (not critically reviewed). Recycled material is considered to substitute virgin material 1:1 (avoided burden approach).

** Carbon footprint of 1kg of Sulapac Universal granules is 0.42kgCO2eq. For typical fossil plastics the corresponding figure is 1.7-3.5kgCO2eq depending on the type of plastic. This means that for every kilogram of fossil-based plastic produced, there is between 1.7 and 3.5 kilograms of carbon dioxide released.

Get the news

Subscribe to our newsletter and keep up with our latest developments and sustainability news.